WH Series

Turbowin’s turbo compressor WH Series is based on air foil bearing technology covering pressure range from 1.5kgf/m² to 9.0kgf/m². Our multi-stage compressors are best suited in industries requiring high pressure of clean air including textile, food & beverage, petrochemical, semiconductor, and shipbuilding.

WORLD WIDEST RANGE

Turbowin’s turbo blower WL Series offers world’s widest lineup of 10 to 1,200 HP. We provide the optimal solutions for various needs of our global customers.

ENERGY SAVING

Old conventional piston and screw compressors incur high costs in terms of installation, maintenance, and energy savings. Turbowin’s turbo compressor requires no other consumables except for filters and can offer up to 57.5% of energy saving efficiency.

Surge Protection System

#Patent: 10-1989588

When entering surge area, sub solenoid valve is activated three to four times to effectively control and protect the equipment from staying in surge area.

Surge Protection System

#Patent: 10-1989588

Sub solenoid valve is activated three to four times when the operating point falls under surge area. This protects the equipment from going to sudden surge and avoid any immediate stop.

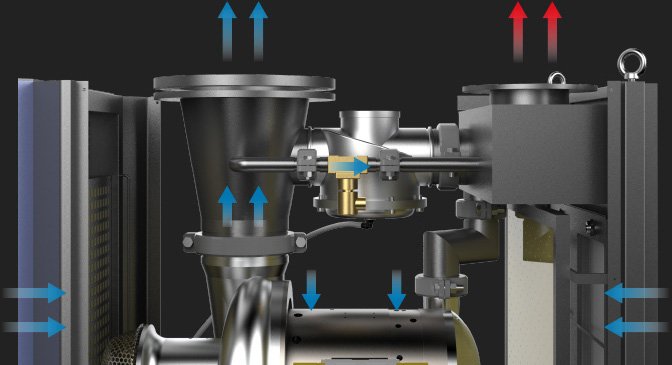

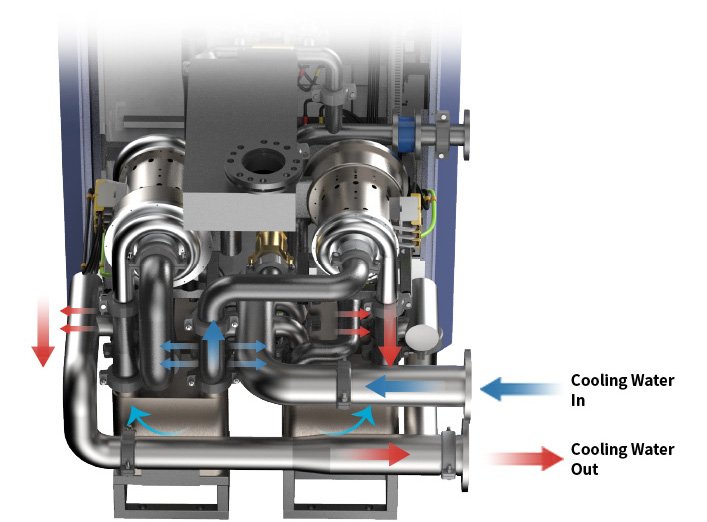

EFFECTIVE COOLING SYSTEM

Based on Turbowin’s patented dual cooling system, no additional cooling system is required, and the inverter is also air-cooled.

High-pressure compressors more than 4bar is installed with inter/after cooling system.

FAQ & Answer

frequency and questions Provide.

100% oil free means it does not contain any oil. Also, unlike the oil-free screw compressor, there is no silicone coating on the rotor surface. No impurities other than air will be added.

Air foil bearing type is relatively simple which requires no bearing controller nor proximity sensor. The structure of magnetic bearing however is highly complex with many sensors and wirings. It is especially vulnerable to unexpected blackouts. This is why magnetic bearing requires an additional power supply to protect the bearing. Air bearing turbo blower is expected to h 5 to 10% higher overall efficiency than magnetic bearing turbo blower. Magnetic bearing turbo blower must be cooled down 70 degrees Celsius for the usage of proximity sensors.